Engineers & Manufacturers of the Heatsponge Economizer

1-866-666-8977

Berner Foods, Dakota, IL represented by Meilner Mechanical

A HeatSponge condensing economizer was installed that resulted in a $ 135,000 utility rebate and annual fuel savings over $ 80,000.

Click here for the case study in pdf format

Art Institute of Chicago, Chicago, IL represented by Meilner Mechanical

It took the efforts of a team of engineers, contractors, and installers to fit these horizontal economizers into the

limited space available, "like building a ship in a bottle" as one of the engineers said. The end result is a project that earned a $ 154,000 utility rebate and annual fuel savings over $ 90,000.

Click here for the case study in pdf format

Projects Gallery

TWO-STAGE ECONOMIZERS

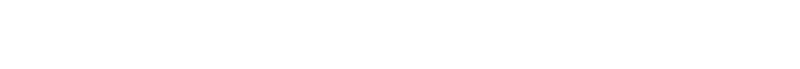

HeatSponge Two-Stage SBS/UB-TITAN model Two-Stage economizer on Superior firetube boiler

The Side-By-Side (SBS) configuration provides an internal three-pass design to maximum condensing and provide a remote sump to insure no condensation can fall into the boiler. The UB is an unbalanced design providding twice the heating surface in the second stage than the first to maximum condening performance. SBS/UB configurations can achieve efficiency improvements of over 12%HeatSponge Two-Stage SBS-BOSS model Two-Stage economizer on Superior firetube boiler

The SBS-BOSS configuration represents some of the larger Two-Stage economizers supplied by BEI. A SBS-BOSS offsets the second stage to reduce overall height and provide for easier accessibility for long term servicing. The fully condensing second stage is provided with exhaust gas flow down for optimum condensing and insurance that no condensation can enter the boiler.HeatSponge Two-Stage SPLIT-TITAN model Two-Stage economizer.

The SPLIT-TITAN configuration is our most compact and cost effecient two-stage configuration.HeatSponge Two-Stage SPLIT-TITAN model Two-Stage economizer installed after Sub-5ppm NOx Selective Catalytic Converters (SCR) meeting the most stringent efficiency and emissions requirements.

HEATSPONGE SINGLE-STAGE ECONOMIZERS

The BOSS/MAGNUM/SUPER/TITAN/COLOSSUS models are the standard HeatSponge economizers used in single-stage applications most commonly conventional boiler feedwater economizer application. Available in carbon steel construction painted in high temperature black or upgraded to stainless steel the HEATSPONGE product range represents the state-of-the-art in indirect contact boiler economizer design.

FULL CONDENSING INTERNAL MULTI-PASS HEATSPONGE ECONOMIZERS

Internal multi-pass economizers (Type III) offer an arrangement unique to BEI. For applications with high levels of cold water usage condensing HeatSponge economizers can be installed in a conventional arrangement utiling the internal three-pass gas flow arrangement allowing for high condensing levels without risk of condensate entering the boiler. The complex engineering to enable Type III arrangements without need for auxilary fans is unmatched by any global competitor and allows for final boiler efficiencies exceeding 92% to 95% HHV.

MAGNUM-11 TYPE-III CONDENSING ECONOMIZERS

SHORTY-MODEL ECONOMIZERS

Used primarily on boilers under 300 HP the HeatSponge SHORTY model economizer is the industry's first replaceable tube element helical coil design. All SHORTY model economizers are manufactured with the tubes, fins, inner and out casings manufcatured out of stainless steel to provide for a maximum logevity.

SHORTY-4 ECONOMIZERS - 150 TO 300 HP TYPICAL RANGE

SHORTY-2 ECONOMIZERS - 80 TO 150 HP TYPICAL RANGE

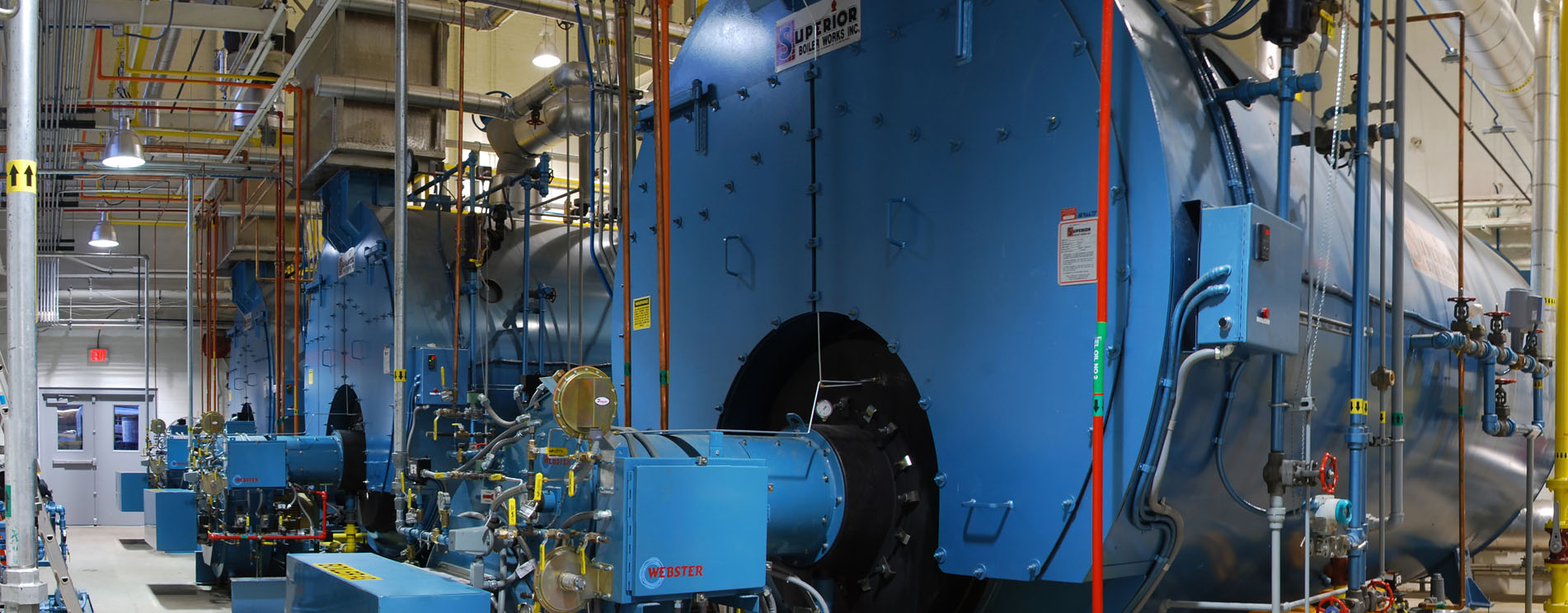

CUSTOM INSTALLATIONS - HORIZONTAL ECONOMIZER

HeatSponge economizers can be installed in custom applications such as these tight-fit 800 HP TITAN model economizers that were specially engineered to work within the extremely tight boiler room space available.

COGENERATION / COMBINED CYCLED HEAT RECOVERY

Two-stage heat recovery off of a 5 MW combution turbine with first stage heat water heating boiler feedwater and second stage servicing an absorbtion chiller water loop. This unit and an identical suplicate are installed at a large dairy facility.

Feedwater economizers for waste heat boilers utilizing the exhaust from combution turbines. These economizers were custom engineered to accomodate the tight dimensions of the installation. These pictures show the progression of the installation. The location of installation is a major US East Coast college.

HEAT RECOVERY DOWNSTREAM OF SCR SYSTEMS

Conventional industrial boiler feedwater economizer installed downstream of a Selective Catalytic Reduction system used for NOx reduction. The economizer was custom engineered to fit into the horizontal arrangement between the SCR and the flue. BEI has the experience and technology to provide cost effective and long lived heat recovery solutions to nearly all industrial applications.

RAINMAKERS / SIDEKICKS

TYPE I CASING

A Type I RAINMAKER arranged for gas flow down exhausting into an ID fan. This economizer is installed as part of a direct contact hot water heating system. The indirect contact RAINMAKER is used to increase the temperature of the water leaving the direct contact section using the hot exhaust gases prior to their entering the spray tower. This system is installed at a medical facility in Europe.

TYPE II CASING

A roof-mounted Type II RAINMAKER designed to preheat make-up water at beverage facility. Due to limited space inside of the boiler room this RAINMAKER was designed to receive exhaust gas exiting the already installed feedwater economizer. being able to utilize a large volume of cold water results in this economizer realizing high-efficiency gains commensurate with its heavy condensing operation. BEI's unique Type II arrangement allows for the exhaust gas to easily tie into the existing stack by teeing horizontally in the top side of the RAINMAKER with the flue gas then turning vertical down for optimum condensing before exiting the lower opposite side into a short stub stack. Large access doors allows for easy long-term inspection and cleaning.

TYPE III CASING

A RAINMAKER with optional Type IIIa casing and moulating damper allowing for full condensing process water heating. The Type IIIa casing is in internal three-pass design so exhaust may enter at bottom and exit through top which the actual heat exchanger is in a vertical down gas flow orientation and isolated sump to optimize performance and insure no condensation can fall down into the boiler. Even with the exhaust gas directional changes the pressure drop is designed to be low enough that the boiler forced draft fan is sufficient to move the exhaust through it. An external fan is not required reducing project cost as well as the parasitic electric loss of an additional fan. The optional modulating bypass damper allows for outlet water temperature control and ability to bypass when firing standby fuel oil.

Type IIIa RAINMAKER's being installed above conventional efficiency steel boilers enabling condensing efficiencies to be realized on a rugged and long lived steel boiler without potential for damage to the boiler from condensation.

HEATSPONGE SHOW UNIT

A show unit HeatSponge economizer installed on the exhaust of a cut-away firetube boiler training and display boiler. This impressive display boiler was built by Ware Inc, one of the BEI's longest tenured and most respected representatives.

HEATSPONGE NASCAR LATE-MODEL STOCK CAR

Work hard play hard, always be competing. Here's a few pictures of the various paint schemes of the HeatSponge stock car over the years as driven by company founder Vince Sands.

Boilerroom Equipment, Inc. division of Thermal Energy International Copyright 2021. All rights reserved.

Boilerroom Equipment, Inc.

11 Rich Hill Road

Cheswick, PA 15024

1.866.666.8977